Technical Specifications

| Two-sided ribbon transfer printing machine ZS-AB 200MM | |||

| Roller diameter | 200MM | ||

| Width(mm) | 600 | 900 | * |

| Power | 5.2kw | 7kw | * |

| Volatge | 110V/220V/380V | ||

| Temperature | 0-400℃ | ||

| Noise | 30QB | ||

| Speed/hour | 80-160m/h | ||

| Packing size | 1430*1060*1610mm | 1430*1060*1810mm | * |

| Installation size | 1850*1300*1800 | 1850*1530*1800 | * |

| weight | 450kg | 550KG | * |

Equipment Advantage

1.Positioning work table,easy to print for the lace products of the single side / double-sided , with more accurate alignment.

heat press lanyard manufacturers Positioning work table

2.Rollers has precision processing for its both inside and outside of cylindrical , with the help of precision grinding of outside and stable roller heating temperature , the printings has no color difference.

heat press lanyard manufacturers Seamless steel pipe drum

3.Rollers has precision processing for its both inside and outside of cylindrical , with the help of precision grinding of outside and stable roller heating temperature , the printings has no color difference.

heat press lanyard manufacturers Imported heating pipe

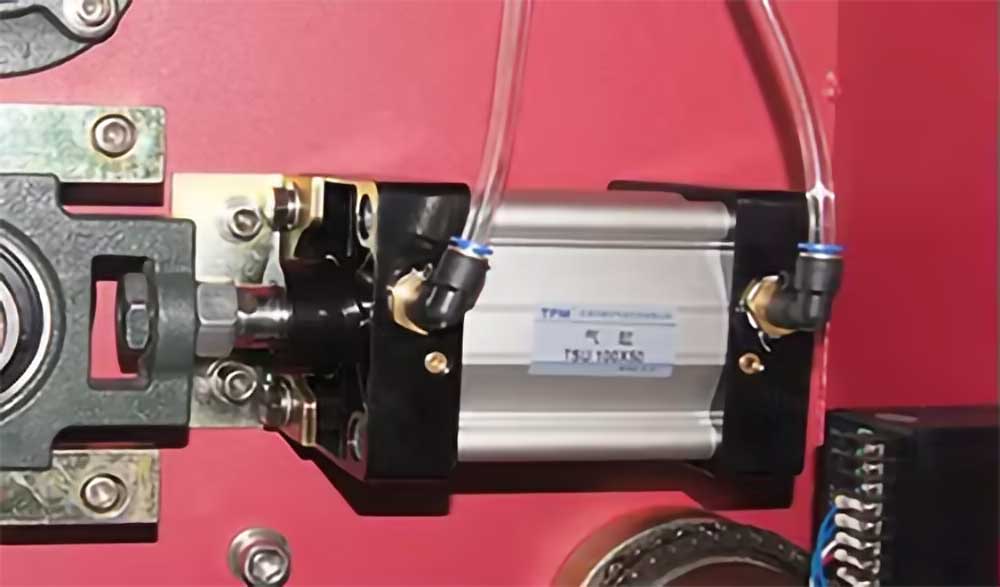

4.Pneumatic pressure (pressure adjustable), the front silicone shaft pressure can give a better transfer effect.

heat press lanyard manufacturers Pneumatic pressurization

5.Transfer printed ribbon go through the belt device, which makes the ribbon easy to roll up without knotting together.

heat press lanyard manufacturers Belt device

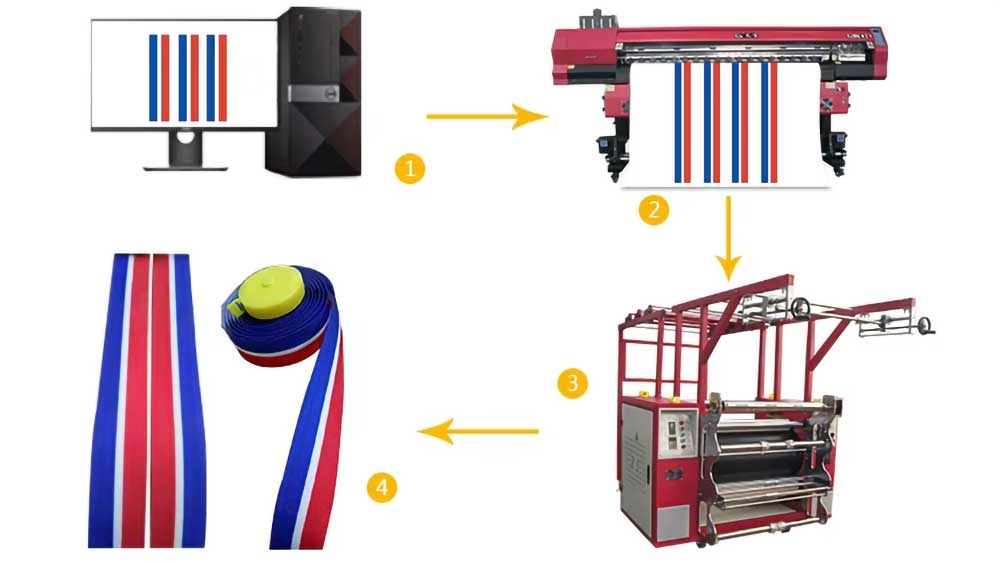

lanyard ribbon heat transfer machine Process

Product Application

This machine applicable to small pieces, webbing ,ribbon, elastic band, shoelaces, mobile phone lanyard, pet belt, zipper and so on.